- Type: Residence

- Location: Purbachal, Dhaka, Bangladesh

- Completion Year: 2019

- Construction Duration: 50 Days

- Architects: Shafinaz Sameen

- Engineers: Mohammad Abu Sadeque

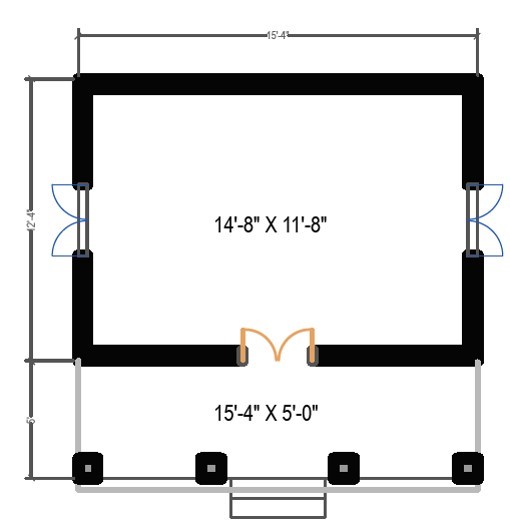

- Covered Area: 190 sqft.

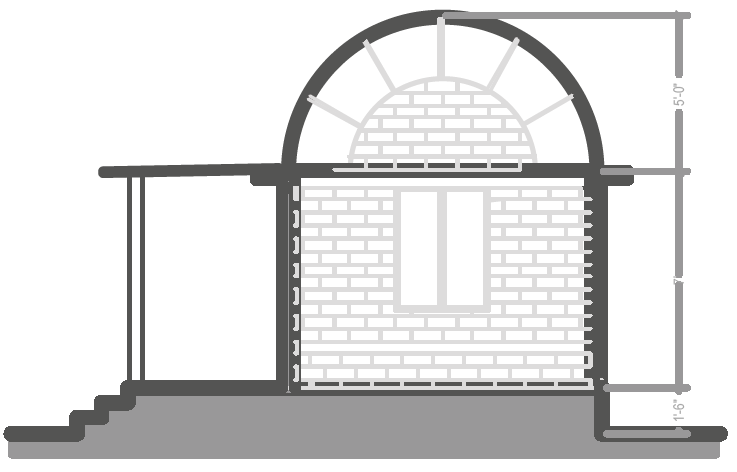

- Materials: Concrete Block, Ferrocement, Glass

- Project Cost: 810 USD

This is one of the pilot projects incorporating building technology innovated by Center for Housing and Building Research (HBRC) for improved sustainable rural houses of Bangladesh and at large. Standard house for living is out of reach for more than 80% of population. Moreover, rural houses of Bangladesh are vulnerable to disasters, are unhygienic, consumes much energy and has a short life span. HBRC house model is for standard hygienic habitation, disaster resilience and affordable to low income population. It is also environmentally sustainable, as it comprises low embodied energy building materials and technologies.

The building technologies adopted here are block masonry and ferrocement. Two types of blocks were used such as Cement Concrete Block and Compressed Stabilized Interlocking Block. Used blocks were made at site by using locally made machineries and non-agricultural sand and soil from river bed coming as a byproduct of dredging to ease navigation. Making of such blocks do not require any burning or autoclave for curing hence consumes minimal energy. Cost of such blocks are remarkably less than that of traditional building materials hence they are affordable. Both pre-cast and cast in situ Ferrocement Technology are used here considering time, cost and quality control. In-situ ferrocement were used in floor and that of pre-cast were used in the roof. Pre-cast technology also applied for casting of door and window frame and shutter. Precast roof elements were joined and fixed using cast in place ferrocement.

In comparison to the conventional semi-permanent houses of Bangladesh, building materials and technologies of such a model consumes low energy (176 MJ/m2) in compare with semi-permanent one (700 MJ/m2). As a result, minimum Green House Gas (GHG) emission occurs as well as provides substantial improvement in indoor comfort and hygiene. Cost of such ferroconcrete roof is much less than conventional reinforced concrete roof. Apparent cost of such ferrocement roof seems to be the same as that of CGI sheet roof with wooden/steel truss but in terms of Life-cycle analysis and social cost analysis the cost of such ferrocement roof is far below. Ferrocement roof provides not only economy and sustainability but improves indoor air comfort. In compare with

CI sheet roof and wall house, it can reduce 5 to 8-degree Celsius temperature during summer period.

New technologies do not require any stone which Bangladesh imports from other countries currently for building construction. Most used building material in new construction is the sand which Bangladesh has abandoned in its river bed which hinders navigation. Structure building process and technologies adopted in this project are simple to implement and user friendly. Only a few days training is sufficient to develop skill for a mason or bar binder. Basic raw material sources for manufacturing of blocks and ferrocement are from river bed sediments or any other non-arable sand and soil. The tools required for production of blocks and precast ferrocement elements are of very low technology and local workshops can make the same without much effort. The technologies are user friendly and beneficiaries will be able to build their houses by themselves. It is not difficult to customize the technologies by using indigenous and locally available raw materials.